MANUFACTURING CUSTOM MACHINERY FOR INDUSTRIAL AUTOMATION

MASTER Ltd. specializes in the manufacturing of machinery, production lines, facilities, and custom equipment for industrial automation. We provide comprehensive services, including design, engineering, manufacturing, and implementation of custom machines tailored to meet our clients specific automation needs.

- Upon receiving a clients request, input parameters, and production process requirements, we develop a conceptual design and an initial project for the required machinery or system.

- Based on the conceptual design, we prepare a price quotation. Once the project is approved and finalized, we proceed to the next stage, which involves 3D design and the creation of 2D drawings for the machines components. These drawings are then sent for manufacturing.

- MASTER Ltd. will create a custom, non-standard machine that complies with all relevant regulations and standards to ensure the highest functionality in the production process.

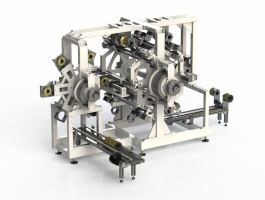

ASSEMBLY AND QUALITY CONTROL MACHINE FOR WITOL

The operator manually places 4 plastic washers for the assembly of 4 Witol components into the nests of the work station. After pressing the START CYCLE button, an automatic assembly and final product inspection cycle is initiated.

Station 1: Manual placement of 4 plastic washers.

Station 2: Automatic placement of 2 screws.

Station 3: Automatic placement of 2 screws.

Station 4: Automatic pressing of the washers onto the screws.

Station 5: Automatic placement of 2 nuts.

Station 6: Automatic placement of 2 nuts.

Station 7: Automatic screwing of 2 sets of screws and nuts.

Station 8: Automatic screwing of 2 sets of screws and nuts.

Station 9: Inspection and measurement.

Station 10: Sorting into good and defective units.

VERTICAL WELDING MACHINE FOR ECO FILTERS

1. At one end of the machine, two pre-assembled individual filters are fed.

2. The machine prepares them for welding by heating their plastic caps.

3. A paper component is fed from the other side of the machine.

4. The machine positions the paper component between the two prepared filters.

5. Welding is performed by pressing the heated caps onto the paper component.

6. The result is a triple filter.

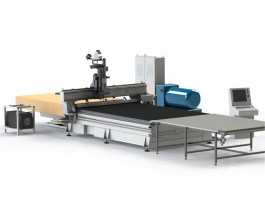

AUTOMATIC LOADING AND UNLOADING OF CNC MILLING MACHINE

1. CNC Portal Milling, Drilling, and Cutting Machine

- Working Area: 3051 x 2139 mm

- Z-Axis Travel: 100 mm

- Positioning Accuracy: 0.01 mm

- Controller: SoftServo/CS-LAB

- Working Table: Vacuum Chamber Table

- Software: MASTER - Mach/SoftServo

- Spindle Motor HSD: 7.5 kW/24,000 rpm

2. Automatic Loading Station for Milling Machine

3. Conveyor Belt for Unloading Processed Parts

Chamfer Machine

This machine is intended for grinding straight-line chamfers with angles ranging from 30° to 60° on sheet material blanks with the following dimensions:

Thickness: 5...20 mm; Width: 100...1000 mm;

Length: up to 3000 mm

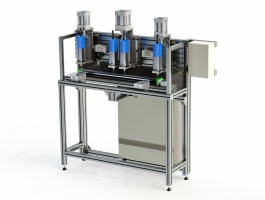

Four-spindle drilling machine

The machine is designed for drilling six holes with a diameter of 4xø2.8mm and 2xø4.5mm at pre-defined locations.

LINE FOR COATING AND ARRANGING PASTRY SHEETS FOR CONFECTIONERY PRODUCTS

1. Coating a sheet with cream.

2. Positioning the sheet on the second line.

3. Coating the next sheet.

4. Positioning the next sheet on top of the previous one.

5. Positioning an uncoated third sheet on top of the previous ones.

6. Advancing the assembled sheets through a calibration roller.

7. Conveying the sheets to the final position for manual arrangement.

| © 2011-2019 MASTER Ltd. All rights reserved. |

|

ruse@master-bg.com |

| design and development by |  |